Introduction

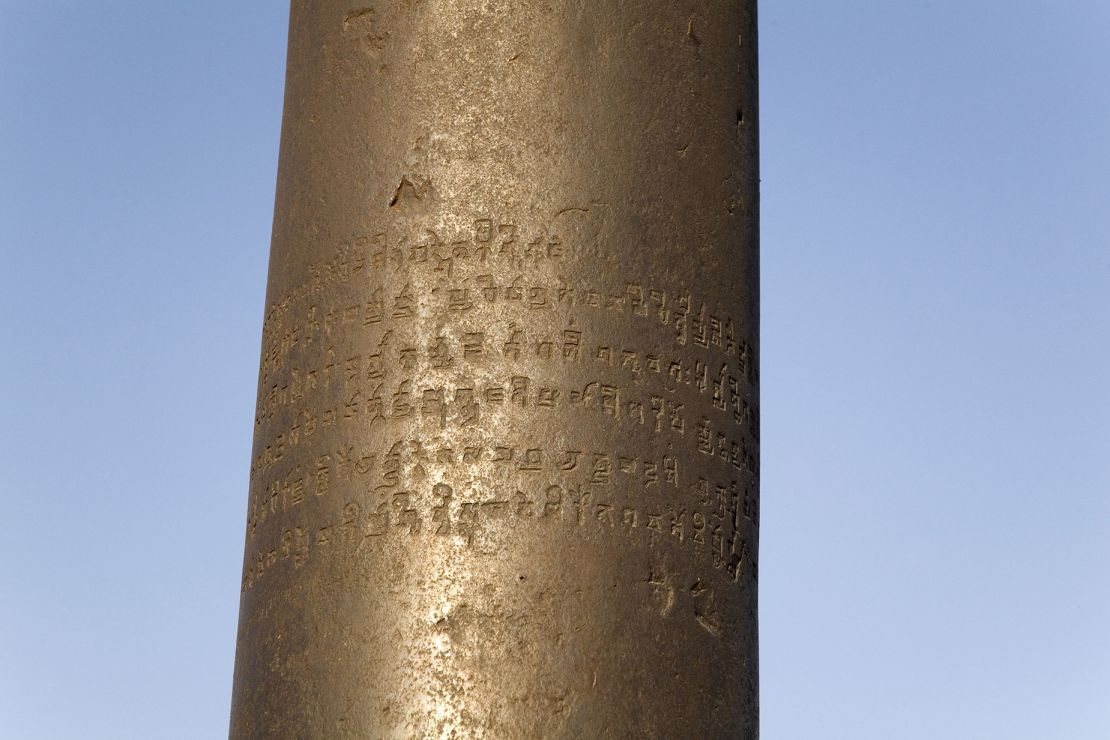

Towering majestically in the heart of India’s capital, the Iron Pillar of Delhi stands as a testament to the remarkable metallurgical prowess of ancient craftsmen. This iconic structure, estimated to be at least 1,500 years old, has long captivated the attention of scientists, historians, and curious onlookers alike.

What makes the Iron Pillar so exceptional is its unparalleled purity and resistance to corrosion. Boasting an astonishing iron content of 99.72 percent, it is nearly free of the impurities that plague modern wrought iron, which typically contains traces of manganese and sulfur. This level of purity is truly remarkable, considering that the technology of the ancient world was not believed to be capable of producing such a feat.

The enduring mystery of how these ancient artisans achieved such remarkable results continues to baffle and intrigue researchers. How did they manage to create an iron structure that has withstood the test of time, remaining virtually rust-free for over a millennium and a half? In this blog post, we’ll delve into the fascinating history and metallurgical secrets behind the awe-inspiring Iron Pillar of Delhi.

The Enigmatic Origins of the Iron Pillar

The Iron Pillar of Delhi is a towering testament to the engineering prowess of ancient India. Standing at a height of 23 feet and 8 inches (7.2 meters), the pillar is made of pure wrought iron and weighs an impressive 6 tons. Its surface is remarkably smooth and unmarred by the ravages of time, a testament to the skill and craftsmanship of its creators.

The exact date of the pillar’s construction is a matter of scholarly debate, but most experts agree that it was erected sometime between the 4th and 6th centuries CE, during the reign of the Gupta Empire. This period is often referred to as the “Golden Age” of ancient India, a time of great cultural, scientific, and technological advancements.

One of the most intriguing aspects of the Iron Pillar is its location. It stands in the Qutb complex, a UNESCO World Heritage Site in the heart of Delhi, surrounded by the impressive ruins of the Qutb Minar, a towering minaret constructed in the 13th century. The pillar’s placement within this historic site suggests that it held significant cultural and religious importance for the people of that era.

The Metallurgical Marvels of the Iron Pillar

The true marvel of the Iron Pillar lies in its exceptional metallurgical properties. As mentioned earlier, the pillar boasts an astonishingly high iron content of 99.72 percent, making it one of the purest iron structures ever created. This level of purity is particularly remarkable when compared to modern wrought iron, which typically contains small amounts of manganese and sulfur, elements that can contribute to corrosion.

The pillar’s resistance to rust and weathering is equally astounding. Despite being exposed to the elements for over 1,500 years, the surface of the pillar remains remarkably smooth and unblemished, with no visible signs of significant corrosion or deterioration. This feat is even more impressive when considering the harsh environmental conditions of the Delhi region, which experiences extreme temperatures, heavy monsoons, and significant air pollution.

Scholars and scientists have long puzzled over the secrets behind the pillar’s exceptional metallurgical properties. How did the ancient craftsmen manage to produce such a pure and durable iron structure, using only the primitive metallurgical techniques available at the time?

The Metallurgical Secrets Revealed

The mystery of the Iron Pillar’s purity and longevity has been the subject of extensive research and analysis by materials scientists and archaeometallurgists. Through a combination of historical records, archaeological evidence, and advanced analytical techniques, researchers have slowly unraveled some of the secrets behind this remarkable feat of ancient engineering.

One of the key factors that contributed to the pillar’s exceptional properties is the unique smelting and forging techniques employed by the ancient Indian craftsmen. Unlike modern iron production, which relies on blast furnaces and other high-temperature processes, the ancient Indian method involved a more labor-intensive process of small-scale smelting and repeated hammering and forging.

The smelting process used by the ancient Indian craftsmen was a technique known as the “direct reduction” method. This involved heating iron ore in a charcoal-fueled furnace, which allowed for the gradual removal of impurities and the production of a relatively pure iron bloom. The bloom was then repeatedly hammered and forged, a process that further removed any remaining impurities and helped to compact the metal, resulting in a denser and more homogeneous structure.

The use of high-purity charcoal as the primary fuel source was also a crucial factor in the pillar’s exceptional purity. Charcoal produced from hardwood species, such as the Indian Sal tree, contains very low levels of impurities, which helped to minimize the introduction of contaminants during the smelting process.

Additionally, the ancient Indian craftsmen employed a unique technique of “carburization,” which involved the controlled introduction of carbon into the iron during the forging process. This helped to further enhance the pillar’s strength and resistance to corrosion, as the carbon helped to form a protective layer on the surface of the metal.

The Enduring Legacy of the Iron Pillar

The Iron Pillar of Delhi stands as a testament to the remarkable ingenuity and metallurgical expertise of ancient Indian artisans. Its unparalleled purity, durability, and resistance to corrosion have captivated the scientific community for centuries, and it continues to be the subject of ongoing research and analysis.

The pillar’s enduring legacy extends beyond its physical presence, serving as a symbol of the rich cultural and technological heritage of ancient India. It is a reminder of the remarkable achievements of our ancestors, who were able to produce such a remarkable feat of engineering using only the limited resources and technologies available to them at the time.

The secrets of the Iron Pillar’s creation have not only shed light on the advanced metallurgical practices of ancient India but have also inspired modern researchers and engineers to explore new and innovative ways of producing high-quality, durable iron and steel products. The pillar’s exceptional properties continue to be studied and emulated, with the hope of unlocking the full potential of ancient metallurgical techniques.

Conclusion

The Iron Pillar of Delhi stands as a testament to the remarkable ingenuity and metallurgical prowess of ancient Indian craftsmen. Its unparalleled purity, durability, and resistance to corrosion have captivated the scientific community for centuries, and it continues to be a source of fascination and inspiration for researchers and historians alike.

The secrets behind the pillar’s creation have slowly been unraveled through extensive research and analysis, revealing a complex and sophisticated process of smelting, forging, and carburization that was well ahead of its time. The enduring legacy of the Iron Pillar serves as a reminder of the remarkable achievements of our ancestors and the vast potential of ancient metallurgical techniques.

As we continue to explore and understand the mysteries of the Iron Pillar, we are reminded of the enduring power of human ingenuity and the importance of preserving and celebrating the rich cultural and technological heritage of ancient civilizations. The Iron Pillar of Delhi stands as a testament to the remarkable accomplishments of the past and a beacon of inspiration for the future.